About

Brazing, soldering and heat exchangers research laboratory is a part of the UK ISM, a unit of the University of Kentucky’s College of Engineering, and Department of Mechanical Engineering. Brazing Laboratory has received support from national and state agencies and science/engineering foundations, such as National Science Foundation, NASA, Department of Energy, Department of Defense, Kentucky Science and Engineering Foundation, as well as from industry.

Laboratory performs fundamental and applied research for development of state-of-the art brazing technologies (such as controlled atmosphere brazing of aluminum, brazing of refractory materials, wetting and spreading of liquid metals). Industrial partners include: GE Aviation, Caterpillar, SAPA, Delphi, HARRIS-Lincoln Electric, Semicon Associates, KB Alloys, and many others. This program combines fundamental research and technological advances relevant for practical applications.

Principal Investigator: Dr. Dusan P. Sekulic

Principal Investigator: Dr. Dusan P. Sekulic

Secat J. G. Morris Aluminum Professor of Mechanical Engineering

Professional Preparation

D.Sc. Eng., Mechanical Engineering, University of Belgrade, Yugoslavia

M.S., Mechanical Engineering, University of Belgrade and University of Novi Sad

B.S., Physics, University of Novi Sad

B.S., Mechanical Engineering, University of Novi Sad

Research Areas: Heat Exchanger Theory and Design, Thermodynamics, Transport Phenomena for Materials Processing

University of Kentucky, College of Engineering

Institute for Sustainable Manufacturing

414F CRMS Building

Lexington, KY 40506-0108

Phone: 859-257-2972

Fax: 859-323-1071

Email: dusan.sekulic@uky.edu

Projects

Brazing of aluminum in space (BRAINS) NASA 2022 – Grant #NNX17AB52G, PI Sekulic, D.P., 6 year contract

Publications

Book

Sekulic, D.P. and Shah, R.K. Fundamentals of Heat Exchangers Design, Wiley, Hoboken, ISBN 978-1-119-88326-5, https://www.wiley.com/en-ie/Fundamentals+of+Heat+Exchanger+Design%2C+2nd+Edition-p-9781119883289

- Gruzd, S. A., Krivilyov, M. D., Samsonov, D. S., Wu, Y., Sekulic, D. P., Mesarovic, S. Dj. (2022) Non-isothermal wetting of an Al alloy pin by Al-Si melt under terrestrial and microgravity conditions, Microgravity science and technology 34, no. 4 (2022): 1-13.

- Wu, Y., Yu, C. N., & Sekulic, D. P. (2021). Si diffusion across the liquid/solid interface of capillary driven (Al–Si)-KxAlyFz micro-layers. Journal of Materials Science, Vol. 56, No.12, 7681-7697.

- Yu, C. N., Lazaridis, K., Wu, Y., Voroshilov, E., Krivilyov, M. D., Mesarovic, S. D., & Sekulic, D. P. (2021). Filling a hole by capillary flow of liquid metal–equilibria and instabilities. Physics of Fluids, 33(3), 034109.

- Shutov, I. V., Kamaeva, L. V., Krivilyov, M. D., Yu, C.-N., Mesarovic, S. Dj. and Sekulic, D. P. (2020) Effect of processing parameters on microstructure in brazing of Al-Si alloys, Journal of Crystal Growth, Vol. 530, 125287. DOI: 10.1016/j.jcrysgro.2019.125287

- Shutov I.V., Kamaeva L.V., Khamidullina A.R., Krivilyov M.D., and Sekulic D.P. (2020) Phase transformations under heat treatment of Al-Si + flux composite brazing metal, Metal Science and Heat Treatment, Vol. 62, Nos. 7 – 8, 498–501, DOI 10.1007/s11041-020-00591-4

- Koehler, T., Yu, C.-N., Schmidt, K., Graetzel, M., Wu, Y., Bergmann, J. P. and Sekulic, D. P. (2019) Development of a repair process for manmade structures in space by using aluminium brazing and friction stir spot welding, Welding Technology Review, Vol. 91, No. 9, pp. 39-50. DOI: 10.26628/wtr.v91i9.1072

- Wu, Y., Lazaridis, K., Krivilyov, M.D, Mesarovic, S.Dj. & Sekulic, D.P. 2023 Effects of gravity on the capillary flow of a molten metal. Colloids and Surfaces A 656, 130400. https://doi.org/10.1016/j.colsurfa.2022.130400

- Lazaridis, K., Wu, Y., Muniyal Krishna, S.K., Yu, C.-N., Krivilyov, M.D, Sekulic, D.P. & Mesarovic, S.Dj. 2022 Contact angle ageing and anomalous capillary flow of a molten metal. Phys. Fluids 34, 112117. https://doi.org/10.1063/5.0123707

Facilities

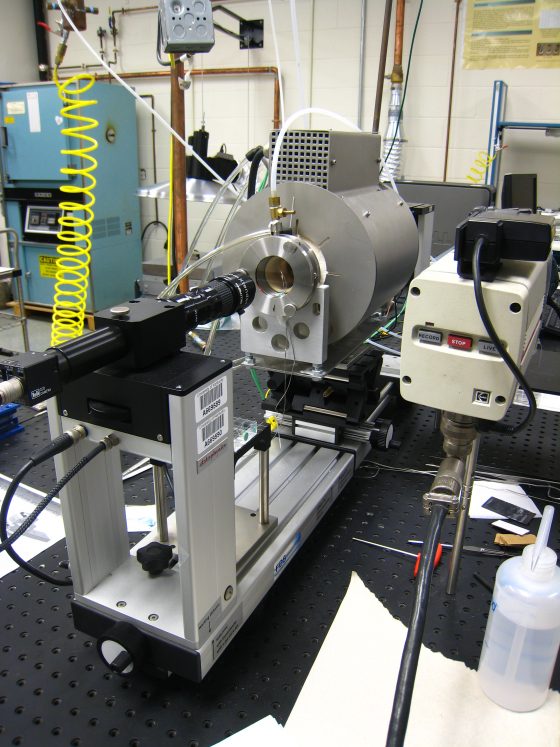

Controlled Atmosphere Brazing Furnace

Controlled Atmosphere Brazing Furnace

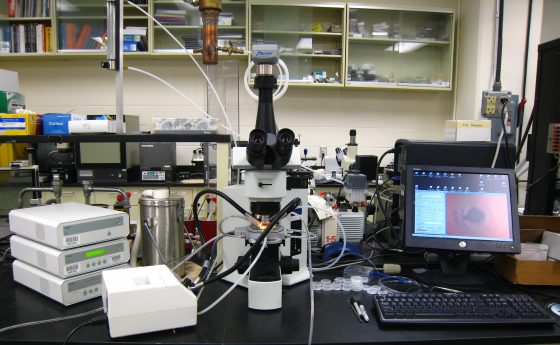

Hotstage Microscopy

Optical Contact Angle Analyzer

Optical Contact Angle Analyzer

Heat Exchanger Analyzer

Casting Furnace

High/Low Temperature Furnace

High/Low Temperature Furnace

High/Low Temperature Furnace

Other Accessible Resources

Electron Microscopy Center, College of Engineering

- SEM, EDS, TEM, FIB

- Metallographic Lab, ISM

- Machine Shop, College of Engineering

- Fabrication services

- Machining Tasks (with assistance of the Sustainable Machining Research Lab, ISM)

- Struers RotoPol-22: Grinding & Polishing with Automatic Doser

- Nikon Ephipot 300: Optical Microscopy System

- Zygo NewView 7300: Surface Profiling - Scanning White-light Interferometer

- >SUN-TEC: Micro Indentation Hardness Tester

- Mazak QuickTurn 10N ATC M/C Â CNC Lathe

- HAAS VF2 4 Axis Vertical CNC Machining Center