On May 29, the University of Kentucky’s Stanley and Karen Pigman College of Engineering held a ribbon cutting ceremony to celebrate the opening of the Next Generation Additive Manufacturing Research Laboratory (NextGen AMRL), the newest addition to the Institute for Sustainable Manufacturing (ISM).

In July 2021, UK, the University of Tennessee, Knoxville (UT) and the U.S. Army Combat Capabilities Development Command’s Army Research Laboratory (DEVCOM ARL) announced a five-year, $50 million collaboration directed toward improving U.S. manufacturing capabilities.

Under the three-way partnership, UK’s project, “Next Generation Materials and Processing Technologies” (NextGen MatProTech), is receiving approximately $24.5 million from the U.S. Department of Defense (DOD).

“As an institution driven by discovery and innovation, we are dedicated to advancing our community and the world. Through this partnership, we can harness our top talents to turn groundbreaking research into real-world solutions — achieving far more collectively than we ever could alone," UK President Eli Capilouto said. "As Kentucky’s institution, we are stronger and more effective when we collaborate in meaningful ways. We are deeply thankful for members of our Congress who continue their steadfast support, which ensures we advance Kentucky and fulfill our promise.”

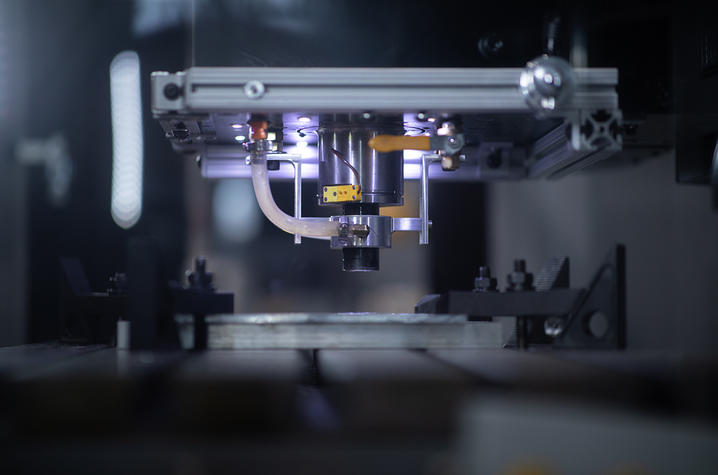

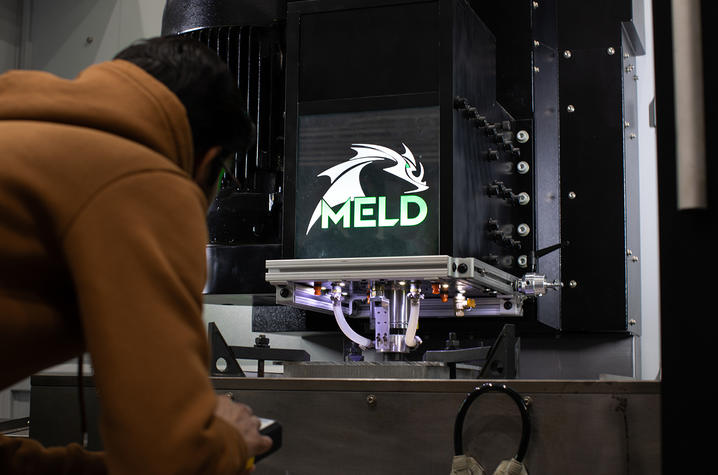

NextGen AMRL features innovative additive and hybrid manufacturing machines, material characterization equipment and systems that facilitate collaborative research among the three partners.

ISM researchers are utilizing these new technologies to push the boundaries of innovation and help establish UK as a world leader in advanced additive manufacturing.

“The NextGen AMRL is a prime example of the type of cutting-edge, collaborative research happening in the UK Pigman College of Engineering,” said Rudy Buchheit, Ph.D., the Dr. Rebecca Burchett Liebert Dean of the Pigman College of Engineering. “Being home to one of the most advanced collections of additive manufacturing tools in an academic setting allows the college to establish itself as a leader in this crucial area of research.”

Following the opening of the lab, UK researchers will work to develop novel materials processing and manufacturing technologies. The goal is to produce superior products and components for the DOD, as well as civilian use.

In addition to increasing intellectual capital, generating new discoveries and identifying high-potential technological innovations, the project is also striving to meet the country’s strategic research needs in materials and processes as identified by the National Academy of Sciences, the National Academy of Engineering and the National Academy of Medicine.

“Kentucky has a long history supporting our nation’s defense, and this new lab at the University of Kentucky stands to deepen our state’s important role in America’s national security. In Washington, I’ve been proud to secure nearly $25 million in federal funding to resource this project and support UK’s leadership in this space,” Senator Mitch McConnell said. “I’m grateful for the students, faculty and university leaders leveraging our state’s advanced manufacturing expertise to assist the Army. For generations, research at our leading universities has fueled America’s growth and secured victories abroad. Today, I’m a proud alum to see UK carry on this honorable tradition.”

Research advances hold promise to address the DOD’s growing needs to maintain global technological superiority by developing higher-performing materials and manufacturing processes. These advancements not only strengthen national security but also contribute to economic growth.

I.S. Jawahir, director of ISM, is the principal investigator (PI) and project director for UK. He also sees NextGen MatProTech, and NextGen AMRL, as a way to make substantial investments in the regional economy.

“The new project will provide tremendous opportunities for the state of Kentucky and the surrounding region,” Jawahir said. “In addition to meeting the DOD’s strategic goals, advanced education and training will be offered for undergraduate and graduate students. This will ultimately support and strengthen workforce development for next-generation manufacturing.”

The UK team has identified three primary research areas: advanced additive manufacturing; novel materials development; and modeling and manufacturing processes for extreme environments, such as hypersonic applications.

UK is also working closely with Flash Steelworks, a new multimillion-dollar plant in Bell County, Kentucky, dedicated to a novel material processing method called “Flash Processing.”

Collaborating with Army engineers and scientists, UK researchers are pursuing new nano-structured metal alloys, and advanced composite materials, using scalable, smart and sustainable novel manufacturing methods.

You can learn more about NextGen AMRL here.

This material is based upon work supported by, or in part by, the U.S. Army Research Laboratory and the U.S. Army Research Office under award number W911NF2120075. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the view of the U.S. Army Research Office.